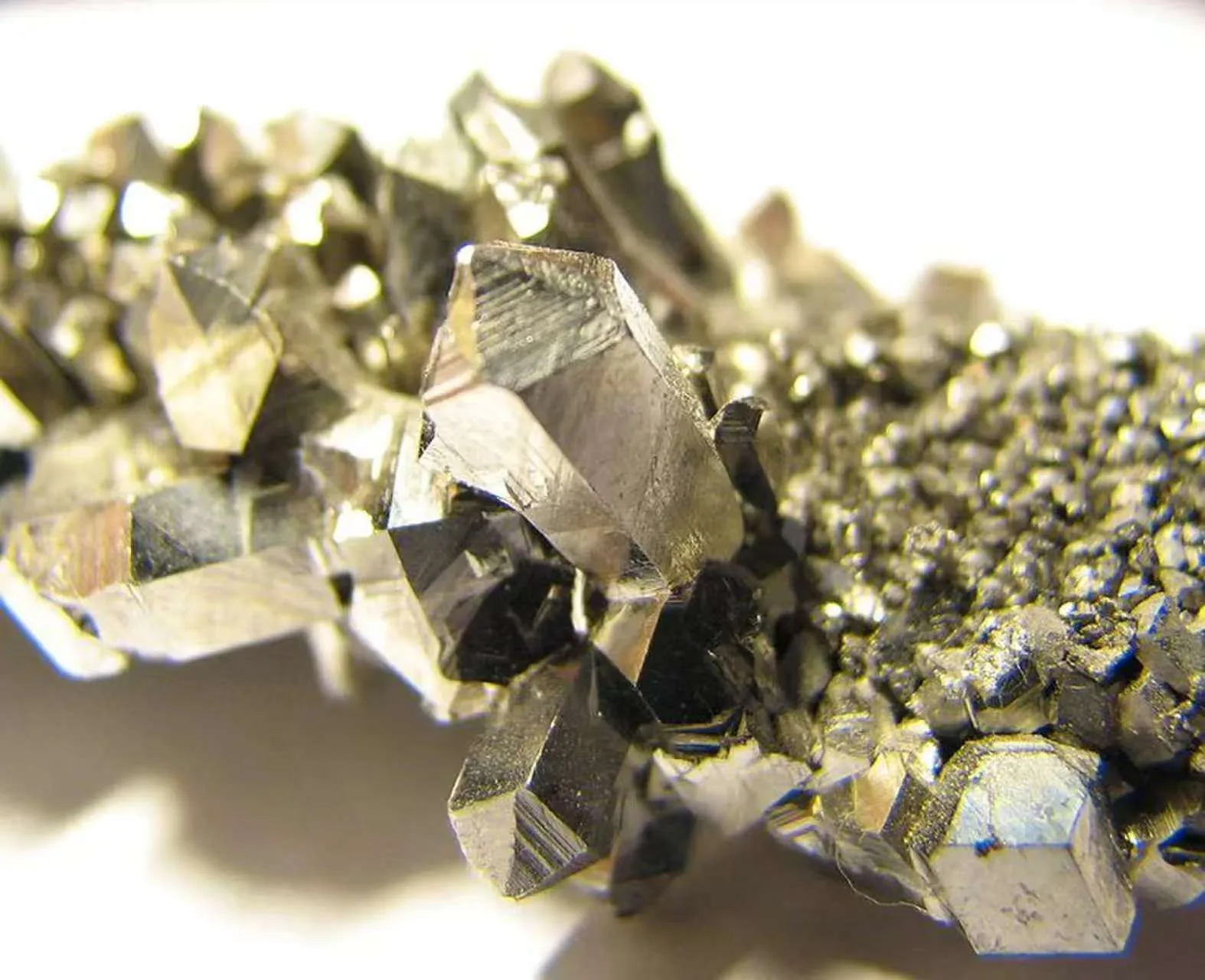

How Tiny Niobium Additives Transform Steel Performance

Niobium’s Core Role: Your Steel’s Microstructure Engineer

You add niobium (Nb) to steel for one revolutionary reason: grain refinement. Just 0.02-0.05% niobium forms niobium carbides/nitrides (NbC/NbN) that:

- Pin grain boundaries during hot rolling

- Prevent uncontrolled grain growth

- Yield 2-3x smaller grain sizes

Result: Steel gains strength without sacrificing toughness – defying the classic strength-ductility trade-off.

The Science: How Niobium Achieves This Magic

Your steel’s transformation happens in three stages:

Stage 1: Precipitation Hardening

- Niobium combines with carbon/nitrogen at 1200°C

- Forms nano-sized NbC particles (5-50nm)

- These particles block dislocation movement

*Effect: Increases yield strength by 100-300 MPa*

Stage 2: Grain Boundary Control

- NbC precipitates pin austenite grain boundaries

- Delays recrystallization during rolling

- Creates ultra-fine ferrite grains after cooling

*Effect: ASTM grain size drops from 5 to 12+*

Stage 3: Secondary Hardening

- Niobium dissolves in ferrite matrix

- Enhances hardenability during quenching

- Boosts temper resistance at 600°C

Effect: Maintains strength in high-temp applications

Why You Need Niobium-Modified Steel: 4 Key Benefits

- Higher Strength-to-Weight Ratios

- Enables thinner structural components

- Weight reduction: Up to 30% in bridges/cars

- Example: POSCO’s Nb-steel for Hyundai EVs (POSCO Report)

- Superior Weldability

- Nb limits carbon migration in heat-affected zones (HAZ)

- Prevents cold cracking in pipelines/offshore rigs

- Critical for API X70-X120 pipeline steels

- Corrosion Resistance Boost

- Niobium stabilizes against chromium carbide formation

- Essential for 400-series stainless steels (CBMM Study)

- Cost Efficiency

- 0.03% Nb replaces 10x more costly alloying elements

- Saves $15-50/ton in high-strength low-alloy (HSLA) steel

Where You’ll Find Niobium-Enhanced Steel

| Industry | Application | Niobium’s Role |

|---|---|---|

| Automotive | Chassis, crumple zones | Crash safety + weight reduction |

| Construction | Skyscrapers, bridges | Earthquake resistance |

| Energy | Pipelines, wind turbines | Fatigue resistance |

| Aerospace | Jet engine components | High-temp strength |

Navigating Niobium’s Limitations

Avoid these pitfalls when alloying:

- Excess Nb (>0.1%): Forms coarse carbides → brittleness

- Low Carbon Steels: Requires precise C:Nb ratio (≥6:1)

- Reheat Cracking: Control cooling rates in welding

Solution: Follow ASTM A1010 specs for niobium HSLA steels

The Global Supply Chain Challenge

- 98% of niobium comes from Brazil’s CBMM mine (CBMM Source)

- Geopolitical risks drive recycling efforts (jet engines/scrap steel)

- Price volatility: $40-50/kg (2024 average)